Researchers at China’s Northeast Petroleum University adapted the traditional Lucas-Washburn model to better calculate the expected level of capillary rise in nano-channels.

From the Journal: Applied Physics Letters

WASHINGTON, D.C., March 21, 2017 — In the last decades, hydraulic fracturing or “fracking,” a method of oil and gas extraction, has revolutionized the global energy industry. It involves fracturing rock with a pressurized liquid or “fracking fluid” (water containing sand suspended with the aid of thickening agents) to draw out small oil and gas deposits trapped in stone formations.

After the water molecules of the fracking fluid are injected into these formations, they rise up the stone walls of the small channels where they have flowed. They can then undergo “imbibition,” a type of diffusion that involves them being absorbed via nano-pores into the neighboring pockets where the oil and gas reside. As the water molecules are absorbed, the oil and gas molecules are displaced and can then be pumped to the surface. This activity is driven by the capillary force between the water and oil, which results from the tension generated at the interface or point where the two fluids meet.

Scientists have typically calculated the expected level of capillary rise in these conditions with the Lucas-Washburn equation, a mathematical model whose earliest parameters were first devised nearly a century ago. The challenge, however, is that that the equation has not been completely accurate in predicting the actual rise observed in nano-capillary laboratory experiments.

“The height of the capillary rise that was observed in these experiments was lower than what the Lucas-Washburn model would have predicted,” explained Anqi Shen, a doctoral student at China’s Northeast Petroleum University who works closely with Yikun Liu, a professor at the university. “Understanding what was causing this deviation became an important point of focus for my colleagues and me.”

The researchers describe their findings this week in the journal Applied Physics Letters, from AIP Publishing.

“Many explanations have been offered for the lower-than-expected capillary rise. One area of discussion has focused on the viscosity of the fluid. Another has been the sticky layers of oil that form on the walls of the capillaries and narrow their diameter, which is an issue that we have also explored,” Shen said, whose work is also funded by the Major Projects Program for the National Science and Technology of China.

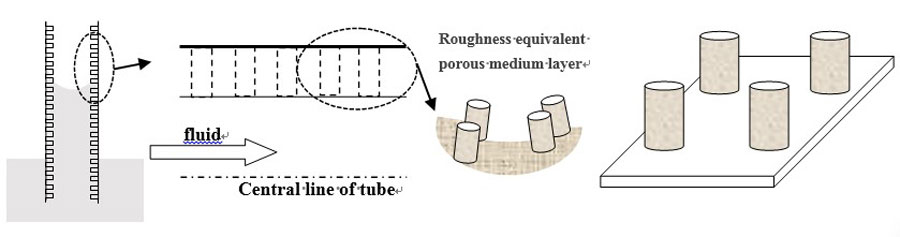

“We looked at many factors and found that the surface roughness of the capillaries was the main reason for the lower-than-expected result. Specifically, we realized that the model could better determine the actual level of capillary rise if we adjusted the parameters to account for the frictional drag that is caused by the inherent roughness of the surface of the capillary walls. When we saw how this made the model more accurate, we knew that we could not ignore it,” Shen said.

Moreover, the miniscule size of the capillaries means that even small increases in surface roughness can make a significant impact on calculations.

“Factors that might be ignored in normal conditions can have significant effects on a micro or nano level. For instance, a relative roughness of 5 percent, in a tube with a radius of 100 cm where the obstacle height is 5 cm hardly affects the fluid flow in the tube. However, with a tube radius of 100 nm and obstacle height of 5 nm, it could significantly affect the fluid flow in the tube,” Shen said.

Currently, there are only a few labs carrying out nano-capillary rise experiments. As a result, Shen and her colleagues could only work with the results from one laboratory in the Netherlands. Going forward, they intend to verify their mathematical formula by examining its effectiveness at simulating the results of other experiments.

Although Shen’s research focuses on oil and gas development, she and her colleagues hope that their work can be of use to scientists working in other fields.

“Capillary rise is a basic, physical phenomenon that occurs in soil, paper, and other biologically relevant realms,” Shen said. “Understanding how it is potentially affected at the nano-capillary level by frictional drag could shed light in a variety of scientific disciplines.”

###

For More Information:

Julia Majors

media@aip.org

301-209-3090

@AIPPhysicsNews

Article Title

A model for capillary rise in nano-channels with inherent surface roughness

Authors

Anqi Shen, Yikun Liu, Xiaohui Qiu, Yongjun Lu and Shuang Liang

Author Affiliations

Key Laboratory of Enhanced Oil and Gas Recovery of Education Ministry, Northeast Petroleum University; Langfang Branch of Petrochina Exploration and Development