Tests on kangaroo shoulder joints reveal how shoulder and knee cartilage behaves differently -- which could lead to improved treatments and better implants

From the Journal: Applied Physics Letters

WASHINGTON, D.C., September 8, 2015 — If you have survived years of pushing, pulling, lifting, lowering and rotational forces assaulting your shoulders, thank your healthy articular cartilage. It is the smooth, white, lubricating connective tissue covering the ends of bones that meet at a joint. Cartilage promotes low-friction movement and helps bones glide pain-free through a wide range of motion and many functions — when it’s healthy.

When cartilage degrades, a host of problems can emerge. Cartilage has limited ability for self-healing or repair. This is why one of the treatments for severely damaged cartilage at modern care centers is surgical implantation of an artificial joint. Yet many of these implants have performance problems.

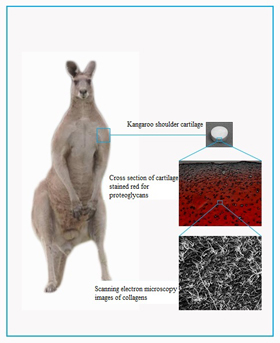

Understanding the biomechanics of natural cartilage could lead to the development of better artificial joint implants. That’s exactly the goal of researchers at the Queensland University of Technology in Brisbane, Australia. The team studied kangaroo cartilage as an analogue for human tissue, and found that a network of collagen protein close to the surface played an important role in helping the cartilage absorb forces without damaging. This behavior was different than that in most studies of knee cartilage, suggesting that artificial knee and shoulder joints may need to be engineered differently.

The researchers report their findings in the journal Applied Physics Letters, from AIP Publishing.

Filling a research gap

The team studies shoulder cartilage issues because the shoulder can sustain injuries and eventually develops osteoarthritis — a growing concern in aging, active populations. “Knee cartilage has been studied extensively. However, there are only limited studies specifically focusing on shoulder cartilage tissues. We think [studying shoulder cartilage] is important, because, especially in sports activities, there is a possibility that the shoulder may get affected by injuries and eventual osteoarthritic development,” said Yuantong Gu, a professor at the Queensland University of Technology who led the team.

The team chose to experiment with the shoulder cartilage of a kangaroo as an analogue for human tissue, which is harder to obtain. The kangaroo is a suitable alternative animal model for the study of human shoulder cartilage biomechanics, the team believes, because the kangaroo has a bidpedal posture, is similar in size to a human (an adult male kangaroo can weigh nearly 150 pounds), and the kangaroo’s grabbing, punching and lifting limb action resembles human shoulder-mediated movements. Sheep, certain rats or mice species, or non-human primates are typically studied as animal models, but lack many of these human-like characteristics.

The team chose to experiment with the shoulder cartilage of a kangaroo as an analogue for human tissue, which is harder to obtain. The kangaroo is a suitable alternative animal model for the study of human shoulder cartilage biomechanics, the team believes, because the kangaroo has a bidpedal posture, is similar in size to a human (an adult male kangaroo can weigh nearly 150 pounds), and the kangaroo’s grabbing, punching and lifting limb action resembles human shoulder-mediated movements. Sheep, certain rats or mice species, or non-human primates are typically studied as animal models, but lack many of these human-like characteristics.

The researchers tested how kangaroo cartilage deformed in an “indentation test,” in which the tissue was pressed by a rounded rod. They then added enzymes to degrade specific components of the cartilage and re-ran the tests.

The team experimented with the degradation of two main components of cartilage tissue: proteoglycans, a type of protein that makes up much of the extracellular matrix between cells, and collagen, the main structural support protein in the matrix, which is also found in hair and nails. Both types of protein affected the load-bearing behavior of the cartilage, but the researchers identified the shoulder cartilage collagen network as the dominant player. This differed from other studies of the knee cartilage that identified proteoglycans as more dominant.

Improving implants

The researchers’ findings highlight that shoulder and knee cartilage could differ significantly in their response to external loadings. The results emphasize the need to engineer an artificial cartilage material to a specific shoulder or knee joint in such a way that it is customized to mimic the different local mechanical environment that the tissue is subjected to within a particular joint, Gu said.

To date, engineered cartilage materials have come across difficulties replicating the biomechanical properties of natural tissue — especially its durability, according to Gu. “We hope to improve the design and manufacture of artificial cartilage materials by applying our improved understanding of the key factors that contribute to the biomechanical properties of the natural cartilage,” he said.

Next, the team intends to validate and refine its findings. The ultimate goal is to apply their discoveries to enhance tissue engineering strategies and to design novel, biomechanically-enhanced cartilage substitutes for shoulder implants.

###

For More Information:

Jason Socrates Bardi

jbardi@aip.org

240-535-4954

@jasonbardi

Article Title

Authors

Namal Thibbotuwawa, Adekunle Oloyede, Tong Li, Sanjleena Singh, Wijitha Senadeera and YuanTong Gu

Author Affiliations

Queensland University of Technology