From the Journal: Physics of Fluids

WASHINGTON, April 7, 2020 — Bottle emptying is a phenomenon most of us have observed while pouring a beverage. Researchers from the Indian Institute of Technology Roorkee discovered how to make bottles empty faster, which has wide-ranging implications for many areas beyond the beverage industry.

Bubbles have been studied extensively for centuries, including early efforts by Leonardo da Vinci who famously noted the sinusoidal rise of bubbles within a pool. The growth dynamics of bubbles at the mouth of a bottle depend on the thermophysical properties of the fluid, the bottle geometry and its angle of inclination. These inextricably intertwined parameters have made bottle-emptying dynamics the next frontier for bubble physicists.

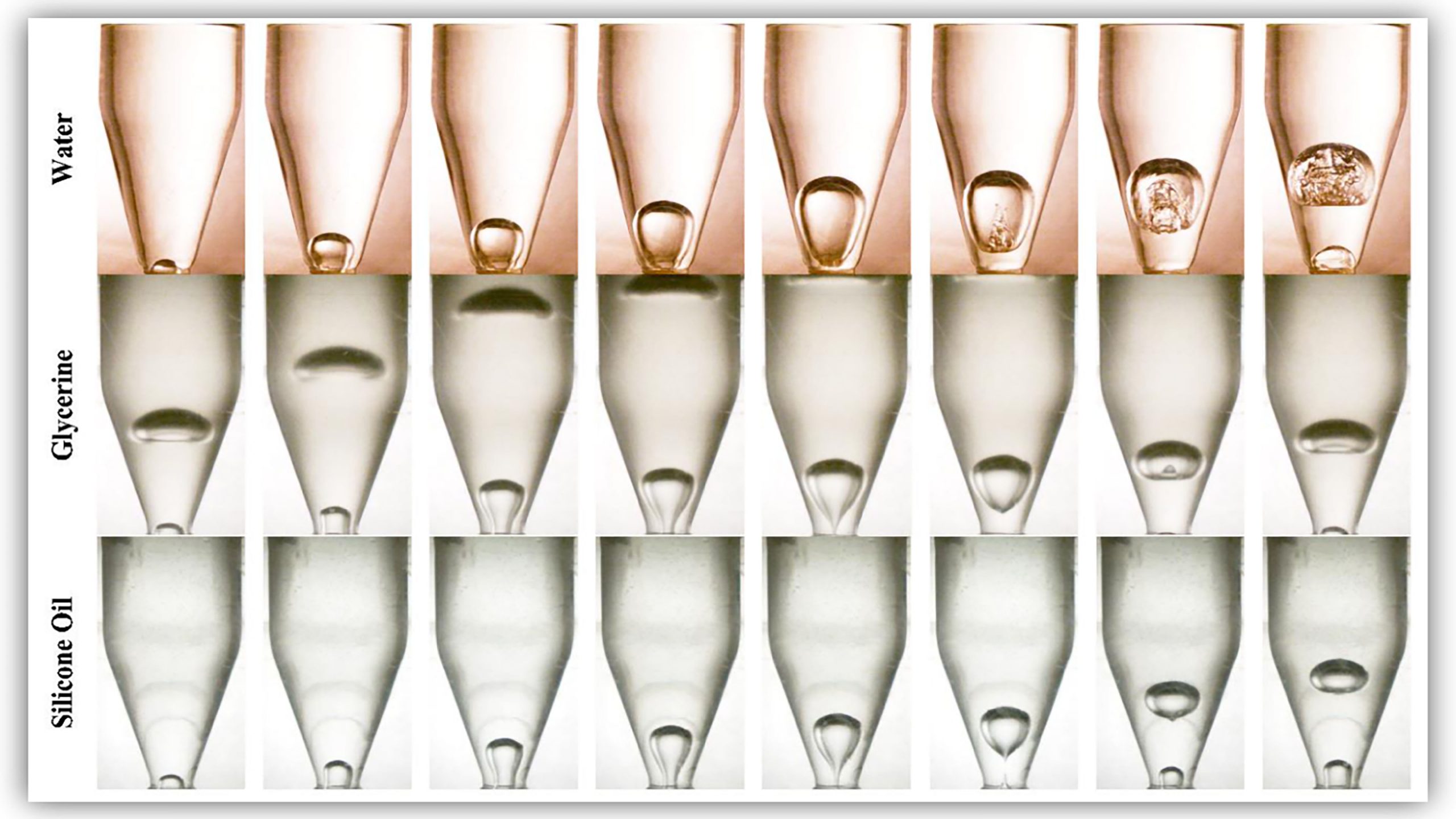

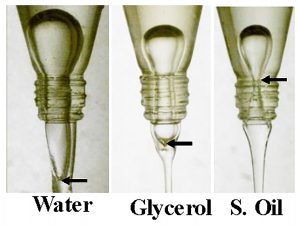

In this week’s Physics of Fluids, from AIP Publishing, Lokesh Rohilla and Arup Kumar Das explore this bottle-emptying phenomenon from the perspective of bubble dynamics on a commercial bottle by using high-speed photography. Image analysis allowed them to conceptualize various parameters, such as liquid film thickness, bubble aspect ratio, rise velocity and bottle emptying modes.

“Bubble dynamics inside the bottle are too complex to study, so we divided the bubble interfacial growth into different stages to comprehend them,” said Rohilla.

It’s well known that a bottle’s emptying time is faster if you increase its angle of inclination. This increases what’s known as bubble pinch off frequency, and the relative increment depends upon the thermophysical properties of the fluid.

“Our experiments suggest there is a critical angle of inclination, after which any further increase in the inclination of the bottle won’t lead to further reduction in the bottle emptying time,” said Rohilla. “This occurs due to the saturation of the voidage, space occupied by air within liquid surrounding, at the bottle’s mouth with the angle of inclination.”

Two distinct bottle-emptying modes were identified. In one mode, the discharge rate is increased due to a high frequency pinch off of air bubbles inside the bottle. In the other mode, it is caused by an increase in volume of the pinched-off bubble at a comparatively lower frequency.

“We’ve also observed an encapsulated bubble while discharging fluid in a vertically upended bottle,” Rohilla said. “Encapsulated bubbles have pinch off sites outside the bottle mouth, contrary to intuition. The presence of a violent ejector jet within inviscid fluids, in which liquid becomes thin due to almost no internal friction, and its complete absence within viscous fluids control the periodicity of the bubbles.”

This work proves that bottle geometry and thermophysical properties play a role in reducing the time it takes for a bottle empty.

“We can manipulate the bottle discharge pattern by manipulating bottle geometry,” said Das. “An intuitive product-specific bottle design will enable better control of its discharge rate.”

The beverage industry and chemical plants are among the applications that will benefit from this better understanding of bottle geometry.

###

For more information:

Larry Frum

media@aip.org

301-209-3090

Article Title

Fluidics in an emptying bottle during breaking and making of interacting interfaces

Authors

Lokesh Rohilla and Arup Kumar Das

Author Affiliations

Indian Institute of Technology Roorkee