Instead of ending up in landfills, leftover grit can be reused to reduce environmental impacts from cement manufacturing.

From the Journal: AIP Advances

WASHINGTON, Oct. 7, 2025 – Cement is one of the most-used materials in the world, and one of the highest emitters of global CO2 emissions. As demand for cement continues to grow, researchers are looking for alternatives to help reduce its environmental impacts.

One alternative could be silicon carbide, an inert substance used as a grit in gemstone polishing. It’s used across the industry at every level of processing, including in hobbyist rock tumblers and industrial-scale saws, grinders, sanding belts, and polishing wheels. Large amounts of silicon carbide waste are produced by the industry, including at the gemstone processing hub in Guangdong Province.

In a paper published this week in AIP Advances, by AIP Publishing, researchers at Wuzhou University and Guangzhou University in China explored gemstone polishing waste as a possible additive in cement. Their goal is to keep silicon carbide waste out of landfills and help reduce emissions from the cement industry.

“The study was motivated by the environmental challenges posed by gemstone polishing waste, a nonbiodegradable by-product rich in silicon carbide,” author Xiaowei Ouyang said. “This problem is massive — cement is a major CO2 emitter, and gemstone polishing waste exacerbates landfill issues globally. Our research focuses on low-carbon materials, offering a way to turn waste into functional additives while addressing climate goals.”

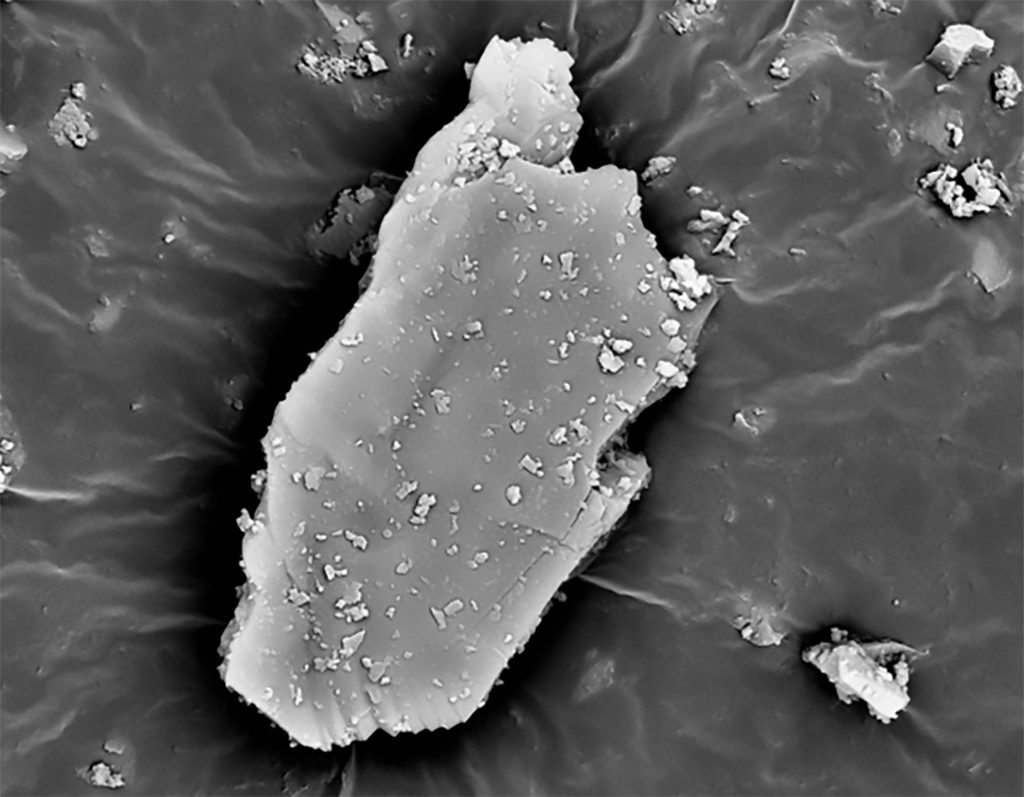

Ouyang and colleagues performed a comprehensive series of tests of gemstone polishing waste as an additive in cement. They tested chemical reactions at the molecular level, as well as microscale characteristics, such as microcracks and pore size, and macroscale outcomes, such as material strength and thermal and conductive properties.

“The most interesting part was the multiscale integration — seeing how nanoscale ion interactions directly influenced macroscale properties like conductivity,” Ouyang said. “What surprised us most was that gemstone polishing waste significantly enhances thermal conductivity up to 159% and reduces electrical resistivity by up to 94% in cement, revealing an unexpected potential for ‘smart’ materials.”

Silicon carbide-enhanced cement could be used in smart materials such as energy-efficient panels for walls or floors that conduct heat for passive heating and cooling, or embedded sensors in bridges that indicate damage by detecting changes in the structure’s conductivity.

One key aspect of the study was measuring how well gemstone waste particles attract calcium ions, which is key in the process of cement hardening. They were able to quantify the particles’ weak affinity for the ions most essential to hardening, which will allow optimization and creation of targeted solutions that use gemstone polishing waste to create stronger cement.

To advance their work, the researchers plan to further optimize the gemstone polishing waste-cement blends, introduce long-term durability, perform field tests, and apply the process to other wastes.

###

Article Title

Authors

Xiongfei Yang, Yuge Gao, Junpeng Wang, and Xiaowei Ouyang

Author Affiliations

Wuzhou University, Guangzhou University